Abrasion Resistance: PU de-logging rollers are highly resistant to the wear and tear caused by rough logs and abrasive bark. This makes them suitable for long-term use in harsh logging environments

Impact Resistance: Polyurethane is known for its ability to absorb shocks, which helps protect the logs from damage during movement and ensures a smooth operation

Durability: These rollers have a long service life due to the inherent strength and resilience of polyurethane, reducing the need for frequent replacements

Reduced Damage to Logs: PU de-logging rollers provide smooth operation, reducing the risk of damaging the logs or harming their natural structure, which is especially important for high-quality timber

Non-Marring: The soft yet durable nature of polyurethane ensures that the rollers do not leave marks or scratches on the logs, preserving the appearance of the timber

Chemical Resistance: PU de-logging rollers can resist exposure to oils, solvents, and other chemicals that may be present in logging operations, increasing their effectiveness in outdoor, rough conditions

Weather Resistance: Polyurethane can withstand various environmental conditions, making PU de-logging rollers suitable for outdoor use in both wet and dry conditions

Customizable Hardness: PU de-logging rollers can be made with varying hardness levels, which allows them to be adapted to different logging needs, depending on the type of wood being processed

Debarking Machines: PU de-logging rollers are used in machines designed to remove bark from logs, as they help guide and move the logs through the debarking process without damaging the wood

Rotating Rollers: The rollers help rotate the logs in the machine for effective bark removal, ensuring that the logs are consistently processed

Log Transfer Systems: PU de-logging rollers are employed in log transfer systems for moving logs from one stage of the logging operation to another, such as from the forest to the mill or from the unloading area to the processing line

Roller Conveyors: Used in conveyors to transport logs for sorting, cutting, or processing, reducing friction and wear on the logs

Sorting Stations: PU rollers help in sorting logs according to size, type, or quality, ensuring smooth movement and easy handling while protecting the wood surface

Wood Processing and Milling

Milling Machines: After debarking, PU de-logging rollers assist in moving logs into milling machines for further processing into timber or wood products

Sawmill Conveyors: Rollers are used in sawmill conveyors to transport logs or timber while ensuring the logs remain intact and undamaged

Timber and Lumber Transport

Log Transport: PU rollers are used to transport timber in various stages of processing, ensuring they move smoothly without causing damage

Material Handling: They are useful in transporting materials or components used in the production of wood-based products such as plywood, MDF, or paper pulp

Reduced Damage to Logs: PU rollers are soft and flexible, helping to minimize the risk of damage to logs, which is especially crucial in high-quality timber production

Increased Efficiency: The rollers help reduce friction and ensure smooth handling, speeding up the debarking and sorting processes in the logging industry

Durability: The high durability of polyurethane ensures that the rollers last longer, even under tough operating conditions, reducing the need for frequent replacements and maintenance

Resistance to Harsh Conditions: PU de-logging rollers perform well in harsh outdoor environments, where exposure to rain, chemicals, and heavy machinery wear is common

Customizable: PU rollers can be manufactured in various sizes, hardness levels, and designs to meet specific logging and forestry requirements, ensuring that they work optimally for different types of logs and processing machinery

Weather-Resistant: They can be used in both wet and dry conditions without degrading in performance, making them ideal for use in forest environments where weather conditions fluctuate

Non-Corrosive: Unlike metal rollers, PU de-logging rollers are not prone to rust or corrosion, increasing their lifespan and performance in wet conditions

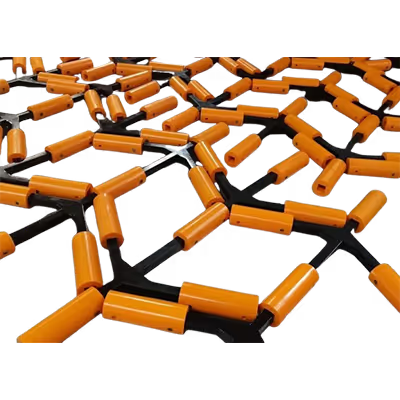

Hardness: PU de-logging rollers can be made in varying hardness levels, from soft to rigid, depending on the specific needs of the logging application

Diameter and Length: Rollers can be custom-made in different diameters and lengths to match the specifications of the logging machinery and the size of the logs being processed

Surface Texture: The surface of the rollers can be smooth or textured, depending on the requirements for grip, handling, and protection during the debarking and transfer process

Coatings and Additives: Special coatings or additives can be applied to enhance the rollers' resistance to UV rays, chemicals, or abrasion, improving their performance in specific environments

Color: PU de-logging rollers can be produced in different colors, which can help in the identification or segregation of various types of rollers in a facility

Regular Inspection: Inspect the rollers regularly for signs of wear, damage, or cracking, especially after prolonged use in rough conditions

Cleaning: Clean the PU rollers periodically to remove any debris or buildup that could affect their performance. Use mild, non-abrasive cleaning solutions to prevent damage to the surface

Lubrication: Depending on the application, lubrication may be required to reduce friction between the rollers and the logs, ensuring smooth operation

Replacement: Although PU de-logging rollers are durable, over time, they may need to be replaced due to wear or damage, especially if they start showing signs of reduced performance